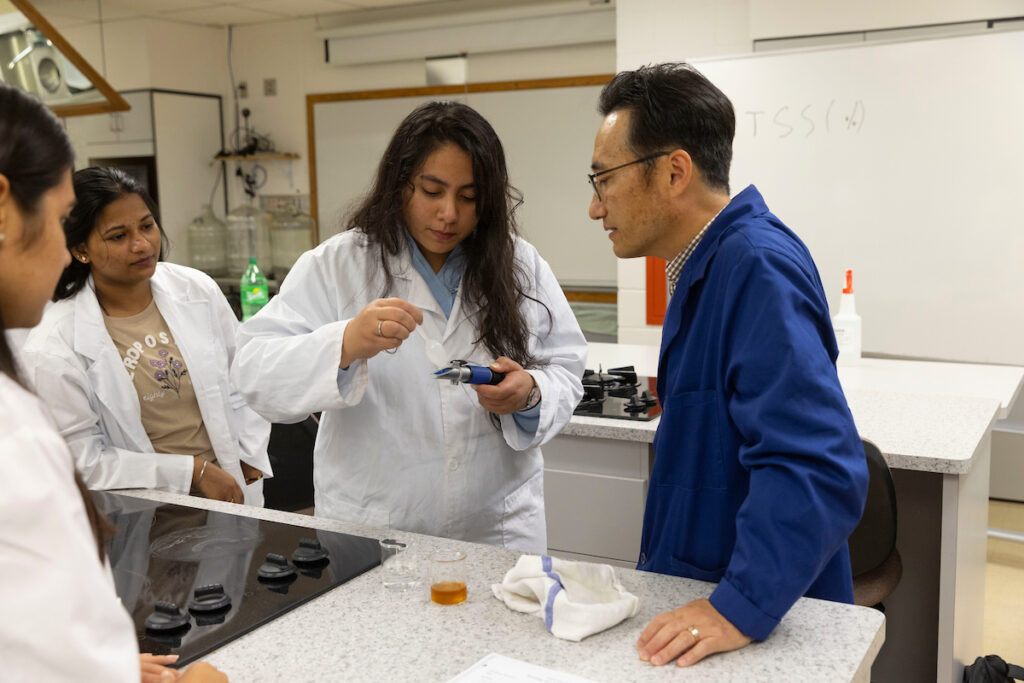

ABOVE PHOTO: Food science award recipients, presenters and faculty at Research Day.

The U.S. Centers for Disease Control and Prevention estimates that 48 million people per year contract a foodborne illness, such as salmonella and E. coli.

To help identify and prevent biological, chemical and physical hazards in food, University of Wisconsin-Stout master’s in food science and technology student Srihaasa Vempatapu and FST undergraduate senior Lainie Carlson researched Hazard Analysis and Critical Control Point – a food safety measurement system used in every stage of the production process.

With forty-two of their food science peers in Professor Taejo Kim’s Food Quality class, they researched HACCP for dairy, juice, meat, poultry, seafood and low-acid canned foods, conducting hands-on testing of foods in the labs.

“HACCP covers the entire food system from growing and harvesting to processing, manufacturing, distributing, merchandising and consumption to reduce the risk of foodborne illness,” said Kim, whose goal is to train students to be qualified quality assurance personnel.

Students presented their HACCP plans and other research at UW-Stout’s annual Research Day, an event showcasing student, faculty and staff research, creativity, and innovation and its impact. Several were awarded for their efforts in the field.

The concept of HACCP was first developed in the 1960s by NASA to assess and implement food safety requirements for the space program. It was presented to the food industry in 1971 through the National Conference on Food Protection.

Vempatapu, of India, thinks HACCP is important because it systematically discovers, assesses and manages possible hazards that could jeopardize food safety.

“HACCP assists in preventing contamination, microbial development and other hazards that could result in foodborne illnesses by concentrating on crucial control points throughout the production process,” she said. “Public health and consumer confidence in the food supply chain are protected by this methodical approach, which also improves quality control and regulatory compliance and guarantees the safety of food items.”

Carlson, of Elk River, Minn., believes that the basic consumer does not know how many steps are taken to ensure safety in their food.

“They just have faith in the manufacturers. HACCP is the reason for that faith. I learned a lot more about the food industry and how important it is to keep food safe,” she said.

Students learned the significance of HACCP’s seven principles and applications, which include conducting a hazard analysis, determining the critical control points and establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping and documentation procedures.

In the U.S., the principles are managed by the National Advisory Committee on Microbiological Criteria for Foods, chartered under the U.S. Department of Agriculture. They are universally accepted by government agencies, trade associations and food industries around the world, such as the U.S. Food and Drug Administration, the European Union’s Food Safety Authority and the International HACCP Alliance.

To become certified, individuals must successfully pass a third-party certification audit, provided by a qualified food safety auditor. Businesses achieve accreditation, verified by a qualified auditor, by conducting a hazard analysis, establishing critical control points and implementing procedures to control those hazards.