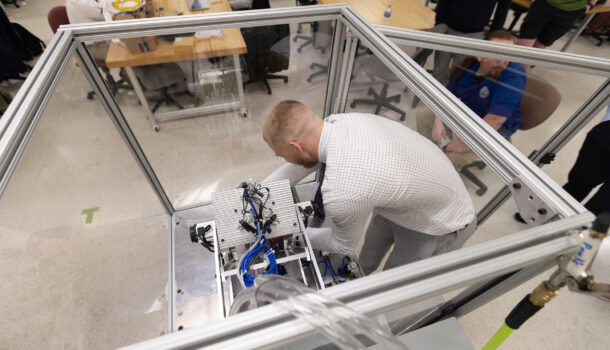

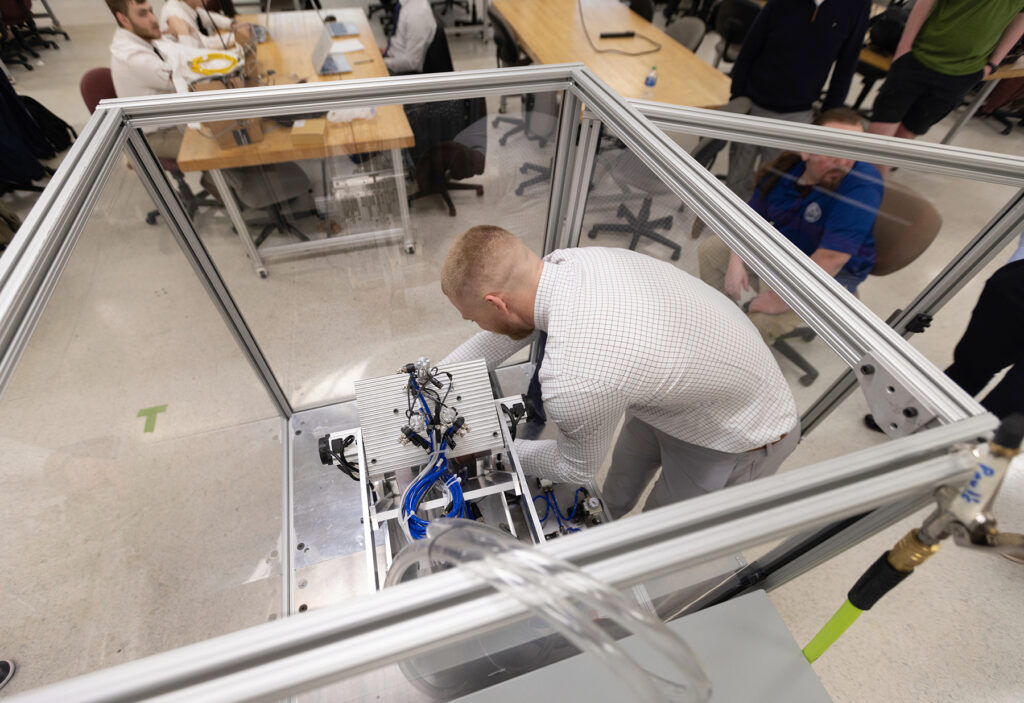

ABOVE PHOTO: Mack Klafter works on the nVent robotic hinge assembly machine.

It was the moment of truth for a team of University of Wisconsin-Stout engineering majors. As peers, professors and industry representatives gathered around, they engaged the manufacturing prototype they had created.

In about 10 seconds, their cube-shaped device housing numerous moving parts and about 250 components perfectly achieved what they had been working on for nine months: pneumatically feeding a hinge to the precise spot where Phillips-head drivers moved in to install two screws into a hinge assembly.

To the engineers looking on, it was poetry in motion.

Presentation Monday, April 29, 10:00 a.m., 217 Fryklund, with a demo at 11:30.

Presentation Monday, April 29, 10:00 a.m., 217 Fryklund, with a demo at 11:30.

The Fryklund Hall lab demonstration was one of 12, preceded by detailed classroom presentations, during the final two weeks of the spring semester Senior Design Experience capstone course. A total of 60 students majoring in manufacturing, mechanical and computer and electrical engineering developed solutions for real manufacturing problems while building their skills and confidence as they prepare to begin their careers.

The hinge assembly project was watched closely by its sponsor, nVent, a growing, $3 billion a year global company based in St. Louis Park, Minn., that makes electrical products. Hinges in some nVent products currently are installed by hand. The UW-Stout team proved it can be automated with robotics.

“It’s cool to see it finally come to life and have the motion we were hoping for,” said Evan Zaves, from Hortonville, a senior in manufacturing engineering. He added that the team did a “really good job with machining” the parts to one-1,000th of an inch to help their prototype operate smoothly.

Other corporations sponsoring student work included Viracon, Fastenal, DiaSorin, Industrial Heat Transfer, Loos Machine and Automation, St. Croix Tactical Manufacturing and Graco. Several companies sponsored more than one project.

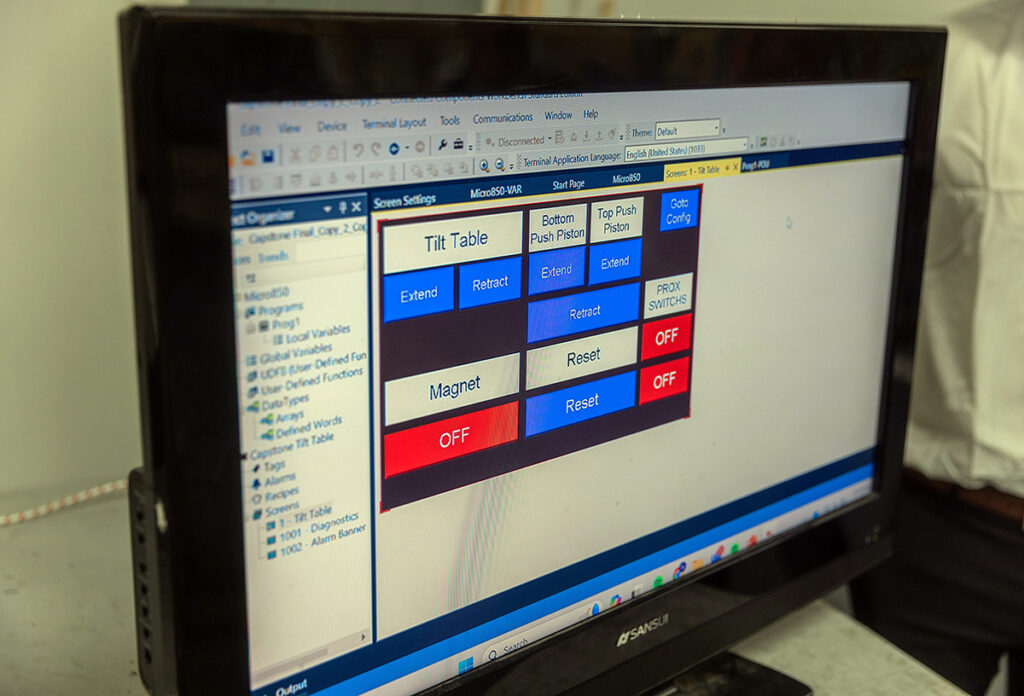

Project challenges, all involving automation of processes, included developing a pressure regulator, adaptive fluid monitor, system to manage machine chips, drill and ream jig, tilt table, material handling cart, mesh shear, part marker for threaded rods and a quality control device for threaded rods.

CLICK HERE FOR MORE ON THIS STORY