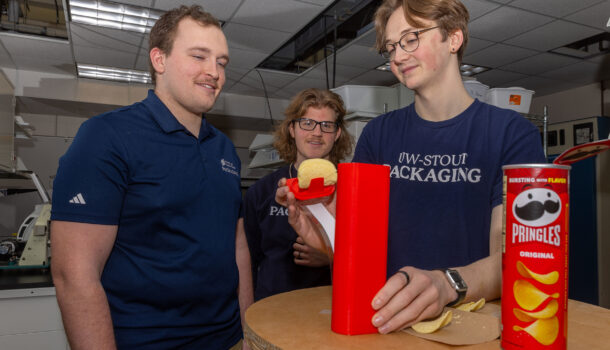

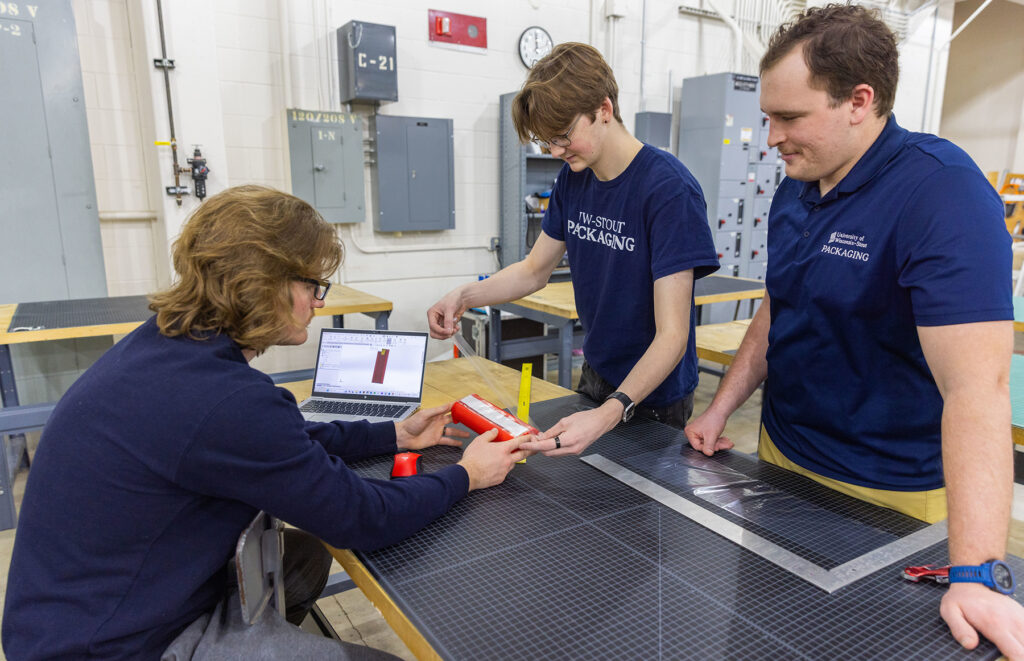

ABOVE PHOTO: The students created their Pringles packaging contest entry in UW-Stout labs. They designed a 3D model before 3D-printing it in a lab.

Imagine creating a new package for a product that has been on store shelves around the world for more than 50 years. How would you make the package better while ensuring consumers still recognized their favorite brand?

“Pringles packaging is one of those things that I’ve always found myself frustrated by but had never thought too far into it…”

That’s the challenge a team of University of Wisconsin-Stout students took on in a competition sponsored by Kellanova, a division of Kellogg’s, and the Packaging Association of Canada. The goal: Redesign the iconic, upright can that holds one of Kellogg’s beloved products, Pringles chips, to improve the Pringles snacking experience.

An innovative design by Lukas David, Ethan Myers and Zach Hoffmire popped to the top, taking first place in February against an invitation-only field of eight other university teams from the U.S., Canada, Germany and the United Kingdom.

What made UW-Stout’s champion entry stand tall? The students:

- Designed an oblong — or in industry terms racetrack-shaped — tube to reflect the shape of the chip, instead of the existing round tube. The new shape would stabilize the product and prevent breakage.

- Made it of recyclable plastic. The traditional can, cardboard with a foil lining and a metal bottom, isn’t recyclable.

- Added a narrow, peel and reseal tab on the curved, front side of the can for better access.

- Redesigned the lid into a tool that could be used with the side tab to push remaining chips to the top, rather than having to tip the can upside down or reach in to get them out.

In the end, it still looked like a Pringles can but was more user and environmentally friendly.

The team won nearly $1,900 and the satisfaction of being recognized by leading industry professionals for their expertise.

Coincidentally, in January, well after competition entries were submitted last summer, Pringles began rolling out a new recyclable can — still round — made mostly from recycled paper, including the base. It also had a recyclable plastic lid, part of an expanded company initiative to make eco-friendly products.

Packaging majors Myers, of Pleasant Prairie, and David, of Johnson Creek, worked on the prototyping. They said the traditional package was overdue for a makeover.

“Pringles packaging is one of those things that I’ve always found myself frustrated by but had never thought too far into it,” Myers said. “To actually be presented with the prompt, it felt very familiar.”

David agreed: “It is a very difficult package to use, and there are a lot of broken chips in the packaging constantly.”

A video demonstrating and explaining features of the design was created by Hoffmire, of Kenosha, a video production major. It was part of the competition submission package.

CLICK HERE FOR THE FULL STORY.